Welding In The Workplace

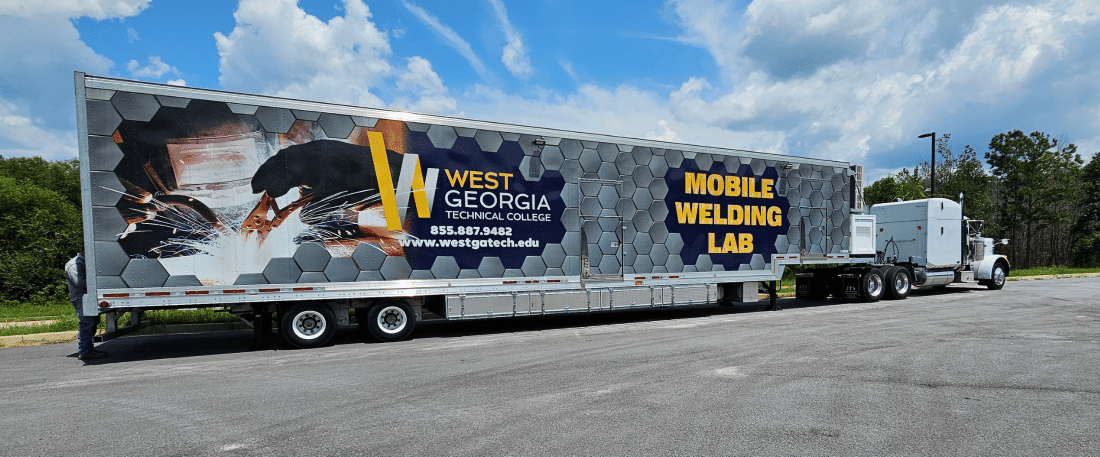

Mobile Welding Lab

Training comes directly to the worksite with the Mobile Welding Lab, offering unmatched flexibility and expertise. Designed for short-term, non-credit training, this state-of-the-art mobile labs deliver high-quality, customized education to industry partners-empowering the workforce with practical, on-site solutions.

The 53-foot self-contained lab is equipped with:

- Six multi-process Lincoln welders

- Complete welding tool sets

- Independent ventilation and air conditioning systems

Key features of the lab include:

- Six high-tech welding booths

- Virtual welders for hands-on learning

- State-of-the-art instructional resources

Contact Us

Contact us at wgtccorporatetraining@westgatech.edu or 706-756-4613 for more information on business solutions for your organization.

Welding Training and Certification for Welders

Our training program is designed to assess and elevate participants' welding skills, from beginner to advanced levels. Each program is tailored to meet industry-specific goals and process certifications. Our American Welding Society (AWS) certified welding instructor provides company-specific, nontransferable certifications compliant with AWS code and Welding Procedure Specifications.

Pre-Training Assessment: Hands-on and Written (Recommended to customize the training program.)

The assessment results will provide a tailored training "prescription," including skill enhancement recommendations and training duration to meet industry requirements.

Written Assessment:

Covers essential knowledge in:

- Basic safety

- Math and measurement skills

- Welding concepts

Hands-On Assessment

Evaluates practical skills such as:

- Metal preparation and weld quality

- SMAW equipment setup and electrode selection

- Welding of five engineering joints

- Completion of V-groove for guided bend test

Welding Skills Offered:

Gas Tungsten Arc Welding (GTAW/TIG)

A precise welding process using a non-consumable tungsten electrode and optional filler metal. Ideal for thin sections of stainless steel and non-ferrous metals like aluminum, magnesium, and copper alloys.

Shielded Metal Arc Welding (SMAW/Stick)

A manual arc welding process using a consumable flux-coated electrode. Suitable for welding iron, steel, stainless steel, aluminum, nickel, and copper alloys.

Gas Metal Arc Welding (GMAW/MIG)

A fast, versatile welding process using a continuous wire electrode and shielding gos. Commonly used in automotive, construction, and manufacturing industries.

Flux-Cored Arc Welding (FCAW)

A high-efficiency process using a tubular wire electrode filled with flux. Widely utilized in construction, shipbuilding, and heavy equipment manufacturing for thick materials.